Advertisement

Propane is heavier than air, which means any escaping gas can end up in your bilge. The results could be deadly.

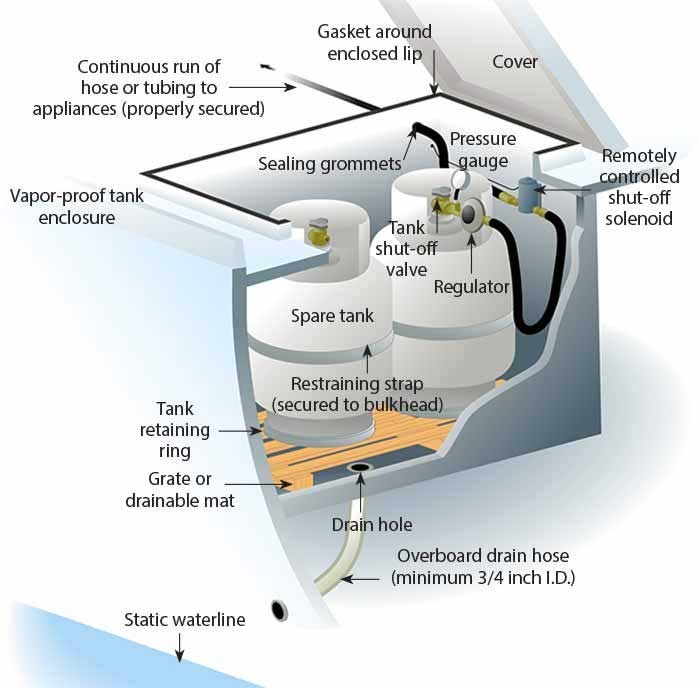

A locker for propane should contain the cylinders, often called bottles, properly secured, and nothing else. Note the drainpipe to safely vent spilled gas overboard away from the boat interior. (Illustration: ©2018 Mirto Art Studio)

Propane (also knowns as LPG) is a great fuel for heating and cooking aboard. It has a high calorific value, meaning it produces a lot of energy for its weight; it comes in handy cylinders; and is readily available. What's not to love?

Not much! But propane does have one flaw — it's heavier than air. This means that any escaping gas from a cylinder, gas line, or faulty appliance will sink to the lowest point it can find, often unnoticed. Because a boat is a confined structure, any leaking propane is likely to end up in the bilge. If enough collects, an explosion from a stray spark is a distinct possibility. While fortunately not common, the BoatUS Marine Insurance files contain numerous claims for propane explosions, which often result in serious injuries. This is another reason, if you needed reminding, for having ignition-protected electrical equipment. Ignition-protected equipment, such as starter motors and alternators, is safe for gasoline-powered engine spaces because they will not produce a spark when operating — one reason why most automotive electrical equipment, often not ignition-protected, is unsuitable for use afloat.

Problems are rare when sensible precautions are practiced in storing and using propane. But as our claims files show, things do go wrong, often with little or no warning, and the results can be tragic. To avoid problems, it's critical that propane is stored and used correctly. The American Boat & Yacht Council (ABYC) has strict guidelines as to how any propane system is installed on a boat.

Cylinder Storage

Whether in use or spares, cylinders should be contained in an approved storage locker. Any locker must be above the normal level waterline of the boat, it should drain any leaking gas to atmosphere, and it must not allow any escape of gas to find its way into the interior of the boat. The gas locker should be used for the sole purpose of storing gas cylinders and no other equipment.

ABYC also specifies that the locker be constructed, or lined, with corrosion-resistant materials. Fiberglass is an almost perfect material for any such locker. Additionally, any gas locker must only be able to be opened from the top and have a latch so that it can be properly sealed closed, although the latch should not require tools to be opened. Finally, because propane is heavier than air, any locker must have a drain at its lowest point that leads over the side so that leaked gas is safely vented away.

Even if a cylinder that is in use is stored properly, all too often we see spare bottles simply tossed into a locker. Not only can these spare cylinders become damaged with the movement of the boat and gear, but should the valve be dislodged or gas escape for some other reason, it likely has nowhere to go except into the boat's bilge.

Tip

Leave It To The Pros

In my role as an accredited marine surveyor, I've seen more than my fair share of MacGyvered installations. These include gas vents that have been teed into cockpit drains with leaking gas unable to drain because water was blocking the hose, loops in vent hoses, no drains at all, and — perhaps the scariest of the lot — a wooden locker containing a couple of large cylinders mounted below the waterline in the engine room of a gasoline-powered boat. I couldn't get off the boat fast enough! In one insurance claim, the owner thought he smelled propane for a couple of days before an explosion ripped apart the deck. Fortunately, no one was seriously hurt. Even if you think you're handy, it's best to leave any propane installation to a pro.

DIY Storage Station

Many small rail-mounted grills use 1-pound disposable cylinders. While these often end up being tossed in any convenient space for storage, the rules concerning their stowage are just the same as for larger cylinders. One of the neatest storage solutions I've seen is a length of 4-inch-diameter PVC pipe attached to a stanchion with hose clamps. The lower end is sealed using a cap with holes drilled in it, allowing any escaped gas to safely vent. The top end has a removable cap for access.

Making The Connection

Propane cylinders, often called bottles, may be made of a variety of materials including steel, aluminum, and fiberglass, but all must comply with specific criteria concerning their construction. Fiberglass tanks gained a bad reputation some years back due to a recall of one company's products (see "Fiberglass Propane Cylinder Recall" below), but a well-constructed and certificated fiberglass tank is safe and offers one distinct advantage over aluminum and steel: the semi-transparent material lets you see at a glance the level of gas remaining inside.

Fiberglass Propane Cylinder Recall

Last year, more than 55,000 fiberglass propane tanks were recalled by the Pipeline and Hazardous Materials Safety Administration (PHMSA). Several of these cylinders, made by The Lite Cylinder Company, ruptured or failed, and a PHMSA emergency order mandated that they be immediately removed from service.

When we attempted to contact the company, though, we discovered that it was out of business, so owners of these cylinders cannot send them back to the company. PHMSA advised us that anyone who owns one of these cylinders should take it to a qualified propane distributor and ask to have it emptied, purged, and the valve removed. Unless the distributor will accept the cylinders for disposal, consumers will have to properly discard them.

Cylinders manufactured by Lite Cylinder with any of the following markings are subject to this recall:

- DOT-SP 14562

- DOT-SP-13957

- DOT-SP 13105 (only if manufactured by The Lite Cylinder Company. Cylinders manufactured by Composite Scandinavia [M0408] and marked with this number are not subject to the recall)

- Any cylinder requalified under requalification approval H706

- Any cylinder manufactured under M5729

PHMSA's Hazardous Materials Information Center can be reached at 800-467-4922.

All propane cylinders, regardless of construction material, have to be recertified 12 years after original manufacture, and every five years after that. This is a fairly simple procedure that often can be completed at the same place that cylinders are filled. Note that excessively rusty or damaged tanks won't be recertified and you'll need to replace them.

The surveyor condemned this installation during an insurance survey. Seawater had entered through a poorly sealing lid and corroded the components inside, which all required replacement. (Photo: Mark Corke)

All connections to the cylinder must be made inside the gas storage locker. T-joints inside the accommodation space supplying more than one appliance are fairly common on some French boats not built to ABYC standards, and are never permitted. Hoses should be of an approved flexible type or copper and be regularly inspected for chafe, wear, and splits. In all cases, the supply line must be one complete unbroken run from locker to appliance.

I've seen compression fittings used to make joints in copper pipe — an effort to save money — but these are not permissible. Only flared-type unions are acceptable. Hose clamps are never permitted with flexible hose installations; they must have permanently attached fittings, such as a swaged sleeve.

Under Pressure

Gas is stored in the cylinder at high pressure, as much as 150 psi, depending on temperature. To reduce this to a pressure that can be utilized by onboard appliances, a regulator is required between the cylinder and the supply pipe. In addition to the regulator, there is often a pressure gauge that, although not mandatory, is a very useful addition that helps when checking the system for leaks. Contrary to myth, the gauge does not show the amount of gas inside the cylinder, but merely the stored pressure that should stay constant until almost all the gas is spent. An electronic, ignition-protected solenoid is often installed to enable the gas to be remotely shut off. Normally installed on the low-pressure side of the regulator, there are some units that can be installed between the cylinder and regulator. The solenoid permits the propane supply to be shut off by simply flipping a switch inside the boat, often close to the stove.

Tip

The manual valve atop the cylinder should also be closed when you're finished cooking and ensures that gas can't leak into the cabin. Solenoids are fairly reliable but some are susceptible to corrosion, so along with the rest of the system they should be regularly checked. Have a helper flick the switch inside the boat while you listen to the solenoid, which should open and close with an audible click. Solenoids are what is known as "normally closed" (they require electrical power to stay open). Remove or shut off the power and the solenoid closes sealing off the gas — a handy safety feature.

CNG

Compressed natural gas (CNG) was popular with boatbuilders for a time, especially in the 1970s and '80s, and there are still some boats that have these systems aboard. CNG has one distinct advantage over propane: It is lighter than air and will therefore not collect in the bilge in the way propane can.

CNG is stored at very high pressures — 3,000 psi or more — and requires special tanks, not unlike those used for scuba diving. Appliances, hoses, and tank fittings designed for CNG are not compatible with propane, and the two systems are not interchangeable.

Checking For Leaks

Any system should be periodically checked for leaks. This procedure is outlined in the ABYC guidelines and is accomplished easily, though you'll need a pressure gauge installed.

With all the appliance valves off, open the cylinder supply valve to pressurize the system. (Make sure the electronic solenoid is switched on, too, if fitted.) Close the cylinder supply valve and note the pressure gauge reading. The pressure indicated should remain constant for not less than three minutes. If a drop in pressure indicates any leakage, check the entire system with a leak-detection fluid or soapy detergent solution to locate the leak. Test solutions should be noncorrosive and nontoxic. If a leak is found, make sure this is corrected before operating the system.

One more safety feature is your nose. Propane is odorless by itself, but it has a smelly chemical called ethyl mercaptan added to help with leak detection. The distinctive rotten-egg smell denotes a leak. If you smell it, shut off the system at the tank and get it repaired immediately.

Detection

Although not legally required, vapor detectors are a great idea and will warn those aboard of a potentially dangerous situation. (See "Three Alarms That Can Save Your Boat"). A small sensor is mounted low down in the accommodation space (often near the propane appliance) and is connected to an alarm panel, usually incorporating a loud buzzer or bell. Even better is a system that will also turn off the propane solenoid at the tank in case of a leak.

The vapor sensor should be mounted low down in the accommodation space, often near the propane appliance.

The alarm panel is mounted at the helm station where it can be easily heard. Some systems can turn off the solenoid when vapor is detected, a plus.

In addition to the fume detector, a carbon-monoxide detector should be installed in each cabin or enclosed accommodation space. Carbon monoxide (CO) is an odorless and colorless gas that is a byproduct of incomplete combustion of gasoline, propane, and other hydrocarbon fuels. And unfortunately, our claims files show that CO poisoning can result in fatalities. Carbon monoxide detectors may be wired into the boat's 12-volt supply or can be stand-alone battery-operated units.