Advertisement

We're often asked how many miles should be expected from a trailer tire. Although automobile tires often list a mileage estimate, trailer tires make no such claim — because trailer tires serve a different function than auto tires. They're designed to prevent swaying under load, often sit in one place for extended periods, and are therefore constructed differently. Rubber-industry experts suggest that about 3-5 years is the lifespan of an average trailer tire, even if it appears to still have good tread depth. More years are possible with exceptional care.

All Cracked Up

Several factors can lead to the early demise of a tire. Topping the list is damage caused by the sun's ultraviolet rays, which often is only visible up close, and appears as tiny cracks on the sidewall near the tread. This is the beginning of the rubber breaking down and should serve as a warning. In addition to sunlight, other factors that exacerbate cracking are extreme road heat from driving fast on hot surfaces, cool winter temperatures that result in contraction and expansion, and finally, sitting on damp ground such as in a grass storage lot. Remove or cover tires when your trailer is not in use for an extended period of time.

Tip

Most tire issues can be avoided by keeping use, load, and inflation requirements within the tire specifications that are stamped on the sidewall, including top speed.

What You Can't See

Improper tire pressure is another major cause of tire breakdown. Maintaining proper tire pressure is the simplest way to extend tire life, if you do a lot of driving. However, you can't easily tell if a trailer tire is underinflated or overinflated by looking at it. Trailer tires are made of stiffer material than car tires to accommodate large loads and to prevent swaying. As a result, an improperly inflated tire doesn't necessarily look obvious, until damage begins to appear.

Read the Signs Causes and Effects of tire Wear

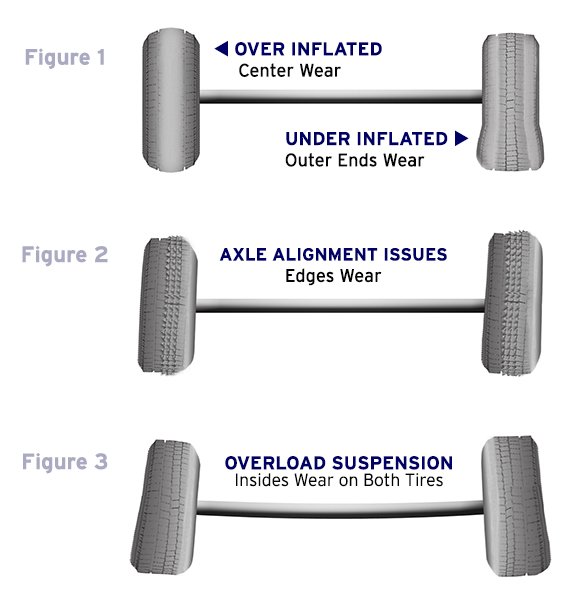

Causes and Effects of Tire Wear Figures

Over Inflation

An overinflated tire will have a narrow contact patch with the road causing the center of the tread to wear at an accelerated rate (Figure 1). Don't make the mistake of simply filling up your tire with air until it's good and hard. Adjust tire pressure when tires are cool to specifications listed on the sidewall.

Advertisement

Under Inflation

An under-inflated tire will wear on both the inside and outside of the tread. Under inflation puts more of your tread in contact with the road and tire edges suffer (Figure 1). If the trailer tire is bulging, chances are it's under inflated. Always carry a tire gauge that reads up to 60 PSI and an adequate 12V tire inflator.

One-Side Wear

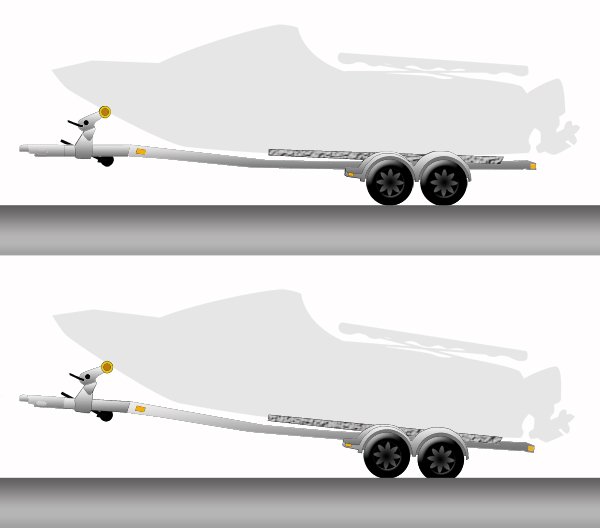

Figure 4: Proper tongue weight is not only a safety necessity, it'll slow down premature tire wear.

When one edge of a tire wears rapidly, it's almost always the inside tread and it happens in pairs. This is usually a result of overloading, sagging suspension, a bent axle or possibly a combination of all three (Figure 3). This happens when the wheel bows out with the top kicking in. A good place to start is to be certain you're within your trailer's load range. Also be sure your trailer is level and that you've got good fore-and-aft weight distribution on the trailer (Figure 4). If that's not the issue, you may be looking at replacing suspension components. Proper trailer tongue weight is a must for safety reasons and lessens premature tire wear.

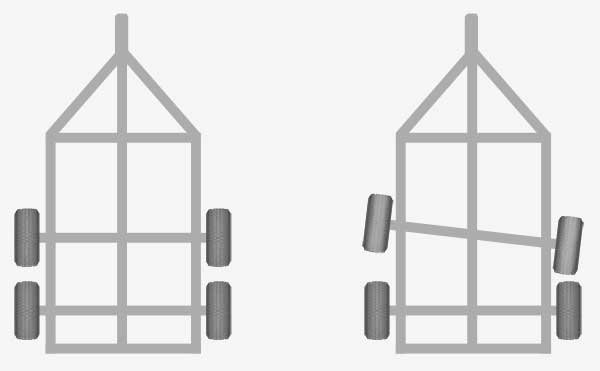

Feathering

Figure 5: Poor axle alignment causes wear on one edge of the tire.

When the tread shows wear on one edge and lessens as it gets to the middle, this is feathering, also known as toe wear — an indication that you have a toe-in or toe-out problem (Figure 2). Correcting this usually requires axle alignment (Figure 5). To determine if your axle is properly aligned, take a measurement from the center of your hub to the trailer tongue. Do this for both sides. If you get two different measurements, your axle is out of alignment.

Random Wear Pattern

Diagnosing the cause of what is referred to as cupped or scalloped wear is a bit of a guessing game. This pattern looks like dips or bald spots in the tread around the edge and can be due to an alignment, suspension, bearing or wheel balance problem. Rotating the tire to another location might help pinpoint the cause. A bald spot in the middle of the tread is usually due to a braking problem or sudden lock up.

Tip

To determine a tire's age, look for the date of manufacture stamped on the sidewall. Most tire issues can be avoided by keeping use, load, and inflation requirements within the tire specifications that are stamped on the sidewall, including top speed.

Let it Roll

Visually inspect your tires before each trip and if you haven't rotated them, spring is a good as time as any. Always keep them aired up to the proper inflation listed and keep out of direct sunlight when possible. Correct any issues with the trailer when you notice them because once a wear pattern starts to develop on a tire it's difficult to stop, even if the underlying problem has been addressed.