Advertisement

When you decide to purchase dock lines, it is possible to be overwhelmed by the variety of rope available. If you are after rope to secure your boat to the dock, you can — and should — ignore most of those spools. Most marine cordage is for general or specialized use aboard sailboats, and the less it stretches, the more it is revered by sailors. For dock lines, however, sailors and powerboaters alike need a rope that does stretch.

Nylon only

In pursuit of dock lines that do not stiffen with age, some rope manufacturers have in recent years begun offering pre-spliced dock lines made from "stretchy" polyester. These may be good for large boats in protected marinas, but for tying your boat to whatever dock, slip, pier, or seawall you might encounter, you should skip right over all rope labeled polyester or Dacron or Kevlar or Spectra or any other fancy name. The right rope for dock lines is plain old nylon.

Nylon has three characteristics that make it ideal for dock lines. It is incredibly strong, it is very stretchy, and it is very good at resisting the harmful effects of sunlight.

The value of strength is self-evident, but the benefits of elasticity may not be as obvious. When your boat surges against an unyielding dock line, the load on the line goes from zero to the maximum at the instant the line comes taut. The likely consequence is a broken line — not unlike how you might snap a piece of thread with a jerk. Even if the rope is strong enough not to break, it is hammering cleats and bitts with every surge. Nylon doesn't come taut suddenly, but dissipates the load by stretching. It is like the difference between hitting the steering wheel or hitting the air bag.

As for nylon's resistance to ultraviolet damage, dock lines — particularly permanent dock lines — live in the sun. Nylon lines enjoy quite a long life in that environment. Polyester is marginally better in this category, but the advantage is insufficient for giving up elasticity.

Nylon actually has a fourth appealing characteristic that you will surely appreciate: it is less expensive. The only exception is polypropylene.

What about polypropylene?

Polypropylene rope is stiff, very slick, and usually bright yellow, but its most distinguishing characteristic is that it floats. You will be familiar with this rope if you water ski. Polypropylene has a relatively low breaking strength, the quality of the rope is notoriously erratic, and because it is so slick, it does not hold a splice. Nevertheless, some boaters use polypropylene rope for dock lines, presumably because it is cheap. This is false economy. Polypropylene suffers badly in sunlight, losing much of its strength in as little as a year. Leave polypropylene to the skiers.

Braid or Three-strand?

Nylon rope is available in both braided and three-strand twist construction. Each has its advantages.

Braided line looks "dressy." It has better abrasion resistance than three-strand, and typically it is slightly stronger. Braided line can be a good choice for tying up in your home dock, but because braided lines have a tendency to snag on rough pilings, I don't like braid for traveling dock lines. (As anchor line, however, braided nylon handles easier and stows more compactly and with less of a tendency to tangle, but at the cost of some elasticity.)

The main advantages of three-strand nylon for dock lines are that it doesn't snag, it is easy to splice, and it is considerably less costly than braided rope. Three-strand also has the significant advantage of being stretchier than braid. As a practical choice for dock lines, three-strand nylon is unbeatable. How often is the best also the least expensive?

What size?

Since larger diameter line takes longer to chafe through, a case might be made for selecting the largest diameter that will fit your cleats. But as the line diameter gets larger, it also becomes less elastic — making the "right" line diameter a bit of a Catch-22. The line diameters shown in the chart should deliver both sufficient strength and the beneficial effects of elasticity.

| Line Diameter | Boat Length |

| 3/8'' | up to 25' |

| 1/2'' | up to 35' |

| 5/8'' | up to 45' |

| 3/4'' | up to 55' |

| 7/8'' | up to 65' |

What length?

For dock lines that are a fixture of your permanent slip, work out the appropriate lengths using old line or light stuff (flag halyard) — making allowances for eye splices — then make up your new lines to those lengths. Nothing is more convenient than pulling into your slip and simply dropping eyes over the mooring cleats. If your dock is fixed — not floating — be sure to leave a little extra length for unusually high or low tides.

For a set of dock lines that travel with the boat, I like lines equal to the length of the boat. It is essential for spring lines to be this long. You can get away with shorter bow and stern lines, but I don't like to sort through my dock lines to place a short one here and a long one there. In a rush, I can grab the one on top and know that it will be long enough. The inconvenience of a line that is too long is far less than one that is too short.

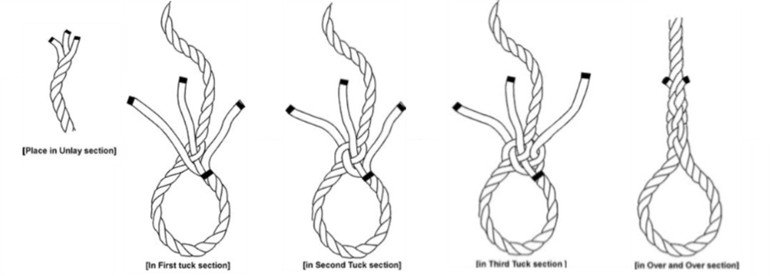

Eye splice

All dock lines should have an eye splice in one end. For permanent dock lines, the eye will be in the boat end of the line, and it should be just large enough to fit over the horns of the boat's mooring cleats. A small eye will be unlikely to come loose, but for complete security you can feed the eye under an open-based cleat before looping it back over the horns.

The eye on transient dock lines generally goes ashore so you can adjust the lie of the boat from on board. Twelve inches is a good eye size, making it easy to pull the line through the eye to form a loop.

A knot, by the way, is a poor substitute for a proper splice. A bowline, for example, reduces the breaking strength of a line by about 40% while a splice retains 95% of the rope's strength.

Chafe protection

Dock line failures are almost always a result of chafe. Unfortunately, it is nearly impossible to rig dock lines so that they never rub against the dock or the boat. Protect your investment — the dock lines and the boat — by sliding a foot or two of heavy-duty hose over each line and tying it in position to take the abrasion.