Advertisement

If your boat has a case of dock rash it could be time to think about repairing and refreshing your gelcoat.

Many owners shy away from gelcoat repairs thinking it's a complicated and difficult project. But with the correct tools and materials, the right attitude, and a little time, professional-looking repairs are within reach for the average boat owner.

Safety

Protect yourself, especially from dust and fumes. Use common sense, and read and understand all the safety instructions that come with your tools and materials. Catalyst is especially noxious; avoid breathing in the fumes. Wear a respirator, Tyvek suit, and disposable gloves. If you get gelcoat on your skin, wash it off right away with soap and water.

Gelcoat is thin, almost like paint, and will run, especially on vertical surfaces. Use several thin coats or use gelcoat paste that is thicker with fewer tendencies to sag. Which type you use will depend on the repair and your method of application. For vertical surfaces, I prefer spray application using several thin coats.

As mentioned, gelcoat has to be sealed from the air for it to harden properly. Otherwise it will stay tacky to the touch. For this reason, you'll often see "waxed" and "nonwaxed" gelcoat for sale. Gelcoat that has wax added will fully cure; the wax rises to the surface after application, sealing out the air and allowing it to cure. Nonwaxed gelcoat can be used when several coats are required, but that means having two different kinds of gelcoat on hand. The simpler way is to always use the waxed kind, lightly wet-sanding the cured surface between coats.

Lenny Makes Her Shine!

In spring 2017, BoatUS Magazine's contributing editor Lenny Rudow held a webinar on maintaining and polishing fiberglass gelcoat, and showed us how to keep our hulls in top condition. After years of boat ownership, and using every product under the sun, he also revealed his personal favorite waxes and polishes, and how best to apply them. You can see the whole webinar on our website, but here's a preview:

- At least twice a season (beginning and end), apply two coats of thick paste wax by hand with application pads; Lenny's favorites are Collinite heavy-duty Fleetwax for Marine and Aeronautical or 3M Ultra performance paste wax. Then buff off with an orbital buffer with removable thick, soft bonnets. Change the bonnet when clogged with wax. (For this thick paste-wax application, he does not recommend liquid waxes with carnauba; that's good for later in the season.)

- Don't forget your outboard cowl. Paste wax to protect it. Then buff it off by hand with a microfiber cloth.

- Don't forget your I/O. Paste waxing your I/O helps deflect marine growth.

- During the season, shower your boat off with freshwater every time you use it. Lenny's favorites for wash and wax products are West Marine Boat Wash N'Shine, Star-brite Concentrated Wash & Wax Power Pine, and Orpine Wash & Wax.

- Later in the season, Lenny's favorite liquid wax is Eagle One Wax As You Dry

To find out about Lenny's favorite ways to remove rust stains from gelcoat; clean and shine nonskid; and for cleaning and sealing stainless steel, see "Restore Gelcoat Shine: A to Z" to watch the webinar. It's full of great tips and techniques.

— Bernadette Bernon

As with all repairs, preparation is key. Just slapping on some gelcoat will give disappointing results as well as look unsightly, and the repair will probably need to be redone within a year or two. It's better to do it right the first time.

If this is your first time repairing gelcoat, start with a fairly small repair in an inconspicuous place. Gain confidence before moving on to more visible spots on the boat.

Tech Support

Tools and Materials:- Respirator

- Latex or nitrile gloves

- Dremel tool with burr-type bit

- Mixing sticks

- Mixing cups

- Plastic spreader

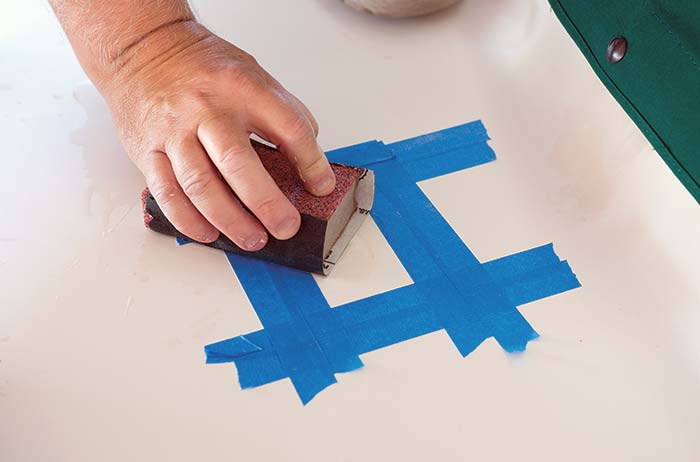

- Waterproof abrasive paper in various grits from 180 to 400

- Sanding block

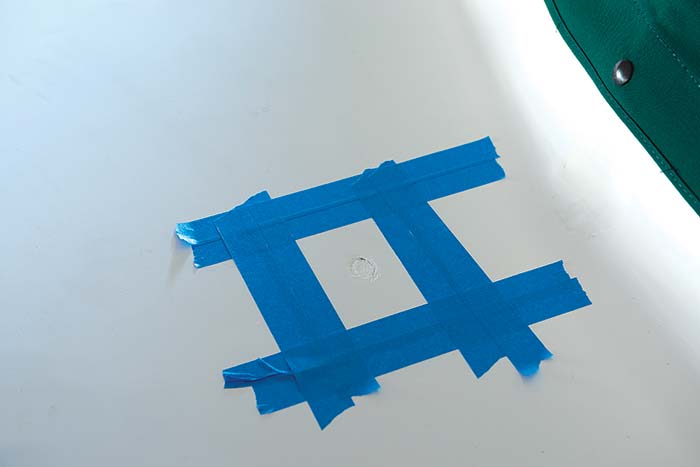

- Masking tape

- Plastic sheet

- Acetone

- Gelcoat

- Styrene for thinning (if spraying)

- Paper towels

- Clean lint-free rags

- Compound and polish

Time: About two hours plus curing time.

Cost: About $25 for materials.

Resources:

Evercoat

Jamestown Distributors

Tap Plastics

West System

Preval

Seaglass, my Grand Banks 32, had a small crack in the top of the forward cabin trunk that needed repairing. Here's how I did it.

Honoring The Epoxy King

You may not know the name, but any DIYer worth his salt knows well his revolutionary creation that altered the way boats are built and repaired. Meade Gougeon, 78, died peacefully at home on August 27. Along with his brothers Jan and Joel, he founded Gougeon Brothers in 1969. Their employee-owned company became world-renowned for pioneering the use of epoxy for marine use.

The Gougeons were behind the formulation and manufacture of West System and PRO-SET epoxies that were like nothing that came before them. Unlike polyester and vinylester resins, then commonly used to bond fiberglass components, epoxies are versatile (bonding to fiberglass, plastic, metal, almost anything), impermeable to water, resistant to osmotic blistering, and much stiffer and stronger.

The advantages of epoxy resins were not lost on professional boatbuilders who were swift to embrace them. DIYers have also come to love the versatility offered by epoxy resins. Metering pumps that keep resin and hardener in the correct ratio, and a range of fillers and fairing compounds, have further extended epoxy applications. Most epoxy the company sells is for fiberglass repairs.

Initially the brothers obtained access to Dow Chemical's laboratories (through a relationship with Herbert Dow, an avid sailor) to develop an epoxy that could be used for coating and bonding. In 1971, Meade launched Adagio — the first large, all-epoxy bonded and sealed wooden boat built without the use of fasteners. The brothers built the 35-foot trimaran, designed by Meade and Jan, in just six months.

They set up their small shop in 1973 in Bay City, Michigan, an epicenter for iceboat racing. They used their groundbreaking bonding process to become the largest builder of iceboats in the United States, and Meade was a champion racer. A year later, they moved onto larger, more traditional boats.

In 1979, Meade wrote The Gougeon Brothers on Boat Construction. This iconic guide details composite construction techniques using epoxy and remains a favorite resource for professionals and DIYers alike. Epoxy boats built by the Gougeons include monohulls, multihulls, and even outrigger canoes, all aided by their tough epoxy construction. The brothers also moved their process beyond boatbuilding to airplanes and even spacecraft.

NASA's Wind Energy Project Office had Gougeon Brothers manufacture epoxy-laminated wood specimens for testing the strength of an epoxy bond between that and a threaded steel rod. The samples were so strong that they broke NASA's testing machine. GBI would go on to manufacture more than 4,000 wood/epoxy wind-turbine blades.

In 2015, Meade was inducted with his brother Jan, who died in 2012, into the National Sailing Hall of Fame. He is survived by his wife of 46 years, 10 children, and 14 grandchildren.

— Rich Armstrong