Advertisement

Two ways to install a transducer that won't compromise your hull.

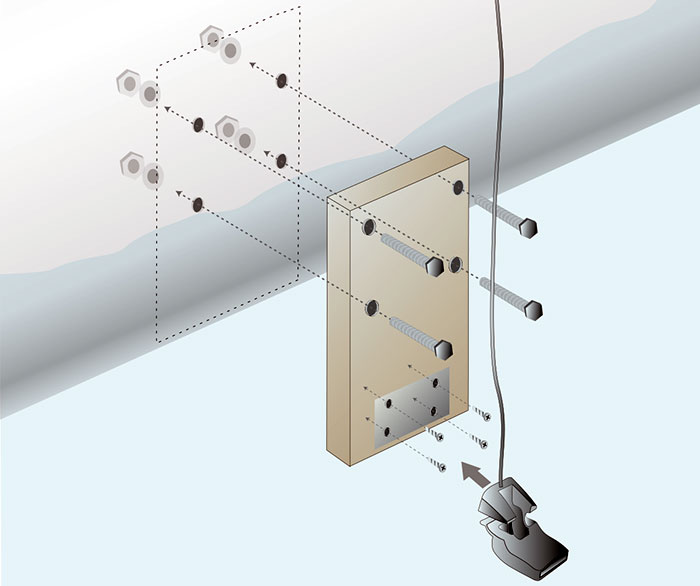

Installing a transom-mounted transducer on a piece of Starboard that is thru-bolted above the waterline prevents transom rot from occurring.

Method 1: Substitute Transom

There are alternatives to drilling a hole in your bottom for a transducer. Transom-mount transducers are common on smaller boats, but the mounting screw holes can allow water in, causing rot in the transom core. Even careful sealing will eventually fail because of the stress of running on plane. A better option uses a piece of "plastic wood" such as structural grade Starboard as a mounting point. Cut a piece long enough to extend from the bottom of the transom to a point at least six inches above the waterline, and several inches wider than the mount. Thru-bolt it to the transom using four stainless bolts. All holes should be well above the waterline and fit the bolts snugly. Dry fit everything, carefully following depth finder instructions, to be sure you've got the right fit and positioning.

Tip

Seal the transom core inside the bolt holes with epoxy resin. Use a syringe to inject the resin into the hole and a Q-tip or toothbrush to spread it around inside. Do this immediately before you insert the bolts. Seal and "glue" the board to the transom with 3M 5200 applied over the back of the board. The bottom edge of the board should be approximately 1/4- inch above the bottom of the boat and far enough above the bottom of the hull to avoid turbulence. Taper the bottom edge of the board, making it parallel to the surface of the water when running on plane. Mounting screw holes in the board now shouldn't puncture the transom; you'll have room for mistakes and the ability to add different transducers later.

— Tom Neale

Method 2: Shoot Through The Hull

If the bottom of your hull is solid fiberglass, meaning not cored, you can shoot through the hull by mounting a transducer inside the boat. I'm not a fan of epoxying a transducer directly to the inside of the hull, although it's definitely the easiest. I prefer to mount the transducer in a plastic pipe, then fix the pipe to the hull.

Fit a piece of plastic pipe to the hull where you want the transducer mounted. Put a wire brush on your drill and clean/ roughen the hull where the pipe will attach. Mount the transducer in the pipe in the same orientation you'd have it if it were hanging off the transom. Seal the mounting holes with the 5200. Leave a half-inch or so between transducer and hull.

A cottage cheese or yogurt container can make a nice bath for a shoot-through transducer if you don't have PVC pipe handy.

Swab the place of pipe attachment liberally with acetone. When dry, use 5200 to fix the pipe to the hull. Fill the pipe with water or antifreeze and you're done. If you want to keep the water/antifreeze in the pipe from evaporating, drip enough hot wax on the liquid in the pipe to seal it. I don't bother with the wax; I use water and only need to refill it once a season. Don't like the spot? Tear up the pipe, clean up the 5200 on the hull with the wire brush, and try another place.

— Jeff Nicolas