Advertisement

Imagine, 96 Upgrades!

Even if you don’t recognize the name, over the years you’ve probably seen Onne van der Wal’s marine photography in boating magazines and yacht brochures. He’s created several books, and he and his wife, Tenley, have their own gallery on Bannisters Wharf in downtown Newport, Rhode Island.

My old friend is driven. He may not have been the first photographer to climb a 165-foot racing-boat mast in the pre-drone era for great overhead shots, or to secure himself to a cleat and dangle over the side in search of a killer angle. But such daredevil shots, and the vision he has for photo composition, became the standard that clients came to expect.

Onne is in his comfort zone when pushing the envelope. As a kid in South Africa, he skipped school to work on fishing boats all over the rough South African coastline. With his machinist’s papers in hand, he applied his engineering skills to the world of boating and eventually became a world-class sailor and ocean racer who competed aboard Flyer, the legendary 1981/82 Whitbread Round-the-World Race winner. It was on that grueling 36,000-mile race that he honed his photography skills, inspired by the drama of the Southern Ocean as the boat, speeding at 30-plus knots, climbed up and surfed down 50-foot waves hour after hour, each time crashing into the frothing, freezing whitewater washing over the decks.

Two old friends get together to talk about boats, old times, family, and the ups and downs that get between us and our cruising dreams

Onne moved to the U.S. in 1985, started his Newport photo studio, and sailed for work – to Greenland, Vanuatu, Patagonia, Antarctica, all over – and he and I worked together on many assignments. We’ve enjoyed a 35-year friendship, even if I found it hair-raising at times. On one of our earliest assignments for a major travel magazine we were snorkeling in the Tuamotus, a watery wonderland of atolls and coral reefs in French Polynesia. As I snorkeled, I heard Onne calling from a distance. He was back on the boat, waving me in. I swam as fast as I could toward the boat, finding myself surrounded by hundreds of black-tipped reef sharks. Nearing the boat, I saw our guide hurling hunks of fish overboard causing surges and splashes among the mass of sharks – and Onne was at the stern taking photos of it all. He was certain of two things: 1. An image of a lot of sharks isn’t nearly as cool as an image of someone swimming through a lot of sharks; and 2. I’d never have agreed to do that willingly, even if he’d asked nicely.

Fast forward to current days, Onne, Tenley, and their three grown kids live in Jamestown, Rhode Island, where in 2016 he refit every inch of an old 1972 Pearson 36, in his driveway. The family had five fun years on that sailboat, until the Covid epidemic. After a day beating home from Martha’s Vineyard, the boat heeling over on her ear, creaking and groaning, everybody wet, and Onne grinding the jib, not quite able to lay the mark, he announced, “I’m done with this stupid stuff! I want something else.”

He’d started thinking about another boat – a stable, more suitable platform from which he could do everything he wanted – photography, filming, fishing, travel, time alone, family time – and one he thought Tenley would enjoy a lot more than the sailboat. He was having warm feelings about trawlers, a pull from his youth, and started looking at Grand Banks.

I visited my old friend last summer, and we caught up with all the things that have happened since he’d found a trawler called Snow Goose, upgraded all her systems himself, and he and Tenley had set off down the coast. The story that follows is in Onne’s voice, as told to my recording device. It’s a story about hard work, resilience, and what happens when you’ve got a dream and think you’re ready to weather the storms, but the storms keep coming from surprising directions, with consequences beyond the sea.

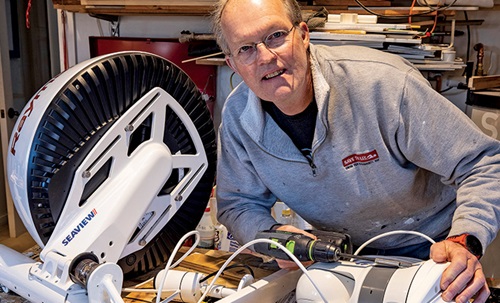

The old mast and boom needed new electronics, a new radar, communications equipment, and wiring, plus a major refinishing

I started to daydream of a boat my wife and I could live on for the winter and cruise down the Intracoastal Waterway, crossing over to the Bahamas for the season. I admit, this wasn’t exactly something Tenley always dreamed of doing. But I just believed that with so much history along the American East Coast, the beautiful scenery, and the comfort of a trawler, she’d really enjoy it a lot more than she liked our sailboat. She decided she was game, that she liked the idea of a steady 8-knot boat that was warm and dry and didn’t heel.

So, in 2020, we sold our sailboat Snoek and started looking for a Grand Banks 36. I’d shot for Grand Banks in the past and knew the company built solid, dependable boats. This was the beginning of Covid, and people were buying boats like toilet paper. I couldn’t find a 36 anywhere, until I ran into an old friend who had a Grand Banks 32.

Tenley and I looked at the boat on the hard. The fuel tanks had just been replaced and the hull was solid. I liked the thickness of the fiberglass. The wiring was organized and well laid out, just old. The wheelhouse and everything below were in good shape. The deck needed sanding. The boat still had a lot of its original hardware and systems from 1986. I thought I might replace most of that. I knew I’d replace the head. It all seemed doable.

Inside, Tenley cleaned every inch of the overhead liner to kill mold and mildew.

Let the work begin

We bought Snow Goose in November 2020. So many of us buy a piece of machinery and just accept that this is where everything should be. On a boat you don’t have to do that. I cut holes where I wanted to put new instruments. Other people would say, Holy hell, are you crazy? You’re cutting into that beautiful teak? I was like, maybe nobody else would, but I’m doing it because this location is practical for me while running the boat. After high school, I’d apprenticed as a machinist, so I can fix stuff and make things. Looking at a project, I get a feeling for how to tackle it in stages. I enjoy the meticulousness of good work and feel proud of it. Sometimes I get more enjoyment out of fixing the boat than using it. That gives you an idea of how much I love it.

I needed a winter to work on the boat, and a summer to sea trial her and make refinements before we started our 4,000-mile adventure. I thought, we’ll go when we’re ready, when the boat’s ready. But I didn’t want to put this off forever because you never know what happens in life. We were targeting the fall of 2022 for heading south.

Tenley suggested we make a list of projects and assign each one a finish date. The list went 96 tasks long. Some were simple, like putting toolboxes on board, or washing, cleaning, painting the bilge. Others were more complex. There was a head to replace, a new flybridge steering wheel and autopilot to install, new electrical equipment, a new nav system, new electrical panel, new voltage meters, USB outlets, new 2/0 wires and AGM batteries, and a new water heater to install. My head began to spin.

I wanted to remove the mast and boom, paint them, and rig them with new electronics in my home workshop. I wanted to assemble and install a stern fortress anchor and spool in the cockpit locker as a secondary and stern anchor. As always happens, as soon as I pulled the cover off something and got into the guts of it, I’d find new things that needed fixing.

There was so much to think about, so I swam three times a week. When swimming, I solve my problems. I’d be doing laps and going through the steps. How am I going to paint the cabin? What bulkhead do I do first? Swimming in semi-automatic mode, I’d think it through and by the time it came time for doing it, I’d have a plan.

The water heater was the original unit and needed to be replaced.

Luckily the company was still making the unit, which fit the same footprint and used the same attachments and fittings. (The popoff valve hose is to come.)

First, replace the head. Then replace all the incandescent lighting on board with LED. Replumb the galley. Paint the forward cabin. And to make even more work, I had to think about how I’d photograph and film each step, because I was making videos of everything I did for my social-media channels and magazine assignments. I had to think, what’s the best angle? Where should the camera be? How should this story start? There was so much to think about that, several times, I’d complete the task and forget to switch the camera on or the audio and have to reshoot it all. Documenting my work on film doubled the amount of time and effort it took to get even simple tasks done. But this is how I make a living, and I hoped to do a book on the project and our trip someday.

If you watch the video of the head replacement, you’ll see what I mean. I start with a shot of the old head. Then a remote camera shows me lugging the old head out, taking it off the boat, and lowering it over the side to my car waiting below. Then I show how I want to reroute the plumbing to make more sense. Then I realize I’d have to fashion a new plate from Starboard because the bolt holes don’t match up. When the work is done, the new head looks – if you can say this about a toilet – beautiful.

Before I started each project, I’d go to a marine store and walk through the aisles, fumbling with pieces and parts, checking diameters, thinking about how many corner pieces I’d need, how many flanges. I’d tell Tenley I was going to the store, and she’d say, “Oh, I’ll come with you.” But I told her she didn’t want to do that. It takes me hours. I walk around and stand and think and stare. An attendant might come up and say, “Are you OK?” I’d say, “Oh, yeah, I’m just trying to figure some things out.”

The flybridge got a big aesthetic upgrade with new canvas cushion coverings, and the teak decks were sanded·, cleaned, and sealed with SEMCO Teak Sealer.

Straight to the source

I tried to use only equipment made in the U.S., or at least mostly assembled here. I wanted to be able to call someone who’d actually designed or built the product and say, “Hey, this is what I’m thinking of doing. Can we talk?” Most manufacturers were happy to help. Some even came to the boat or sent photos or instructional videos. If I got confused, I’d call Joe in manufacturing of XYZ company and say, “I’m stuck with this wiring diagram. Can you explain it?” and he’d say, “Sure. This how we do it here.” I’ve worked in the marine industry for many years and was able to get good deals from manufacturers; but I’d never write about anything that didn’t work well.

I chose Raymarine for navigation devices, and a local technician came down to the boat a couple times to sketch out the basic layout for me. I worked off his plan, and he taught me a lot. The huge advantage of doing all the work yourself is, when you’re at sea, if something breaks, most times you can fix it. When you hear a different rhythm from a running pump, you say to yourself, that’s not right. I know that filter is sucking air and is blocked. And you go change out the filter. Ten minutes later, everything is OK again. This scored me considerable points with Tenley.

I posted videos on Vimeo, Facebook, and YouTube showing how I thought everything through, how I did it, and also when I needed help.

I wanted to replace the original 1986 analog meters on the control panel to see what was coming in from the solar panels, shore power, or generator, and what was being consumed by boat systems. I needed help and called Michael Garretson at Sea and Land Yacht Works in nearby Wakefield, who suggested I replace the boat’s whole power-management system, which meant all-new batteries and heavy-duty wires, and install new switches and gauges. This was daunting. But once I studied Michael’s schematic, it became clearer.

I used Blue Sea Systems ACR switches to connect and disconnect batteries in different states of charge. Mike helped me understand the sequence and schematics. The controllers had complicated wiring so I built the panels in my little shop so I wouldn’t have to stuff my 6-foot-3 self into tight crannies in the engine room to do the work; I could just bring the finished panels to the boat and install them all at once. Mike stopped by to see how I was doing. Between visits, I’d make lists of questions. Without his help, I couldn’t have done this project.

I also installed a Blue Sea Systems tank monitoring sensor, using a hole saw to cut into the top of the fiberglass holding tank to place the sensor, which would allow us to see exactly how full the holding tank was at any time. I installed Hamilton Ferris Power Systems F200 2S watt solar panels to generate power. The end result is a clean, functional instrument panel showing the state of the charge on all batteries.

Finally, it was time to strip Goose’s cabin and saloon sole. I glopped a thick coat of TotalBoat stripper on everything and left it for 24 hours. I stripped the hatch covers in my shop and, using a 4-inch egg flipper, sloughed off 98% of the old varnish, then sanded off the rest with 80-grit paper on my Festool sander connected to a vacuum system, then sanded it all with 160-180-grit. I wiped it down with dewaxer and a rag, then brushed on two coats of the company’s wood sealer varnish that soaked right in. Then I applied two coats of lust gloss varnish with a finish coat of lust matte. The reworked sole looked like new.

One day an older woman came up to me in the supermarket. She was in her 80s and said, “I loved the video of how you replaced the toilet on the boat.”

I said, “Are you a boater?” She said, “No.” I said, “Do you like to work with your hands?” She said, “Not particularly. I just loved the way you told the tale.” Refitting a boat is such a long slog, and she made me happier than she will ever know.

Most of the time, the main saloon had an organized array of every tool needed for the project at hand.

Snow Goose’s saloon received all new lighting· and new upholstery·. Onne also stripped and refinished the teak sole·. Left:

Plans take a dramatic turn

After that first winter, we put Snow Goose in the water to cruise around and see what else needed doing. I could see I’d be working on her through a second winter. In June of 2021, when Covid started lifting, I flew to South Africa to visit family. Back in Rhode Island, Tenley had a regularly scheduled mammogram that showed a small calcification. They did a biopsy. She had HER2+ breast cancer. Not long ago, that could have been a death sentence. We were shocked. Tenley felt so healthy at the time and became defiant. She told everybody that this wasn’t going to kill her, like it was never even an option.

The cancer was caught early, but there was more bad news. It was in more areas than doctors initially thought. She was told chemo alone wouldn’t cure that. She had surgery, a lumpectomy. The doctors removed 10 lymph nodes. Then she started chemo and that long, exhausting grind. During chemo, she caught Covid.

I continued to work on the boat while Tenley was undergoing chemo. Life went on. I knew I couldn’t fix her cancer, but I could still fix the boat. She was fighting and was so positive about the future. I wanted to make Snow Goose perfect for her, so when she got better we could point her bow south and take the Goose down the ICW.

Tenley fought. The chemo wiped her out, and when she finished it, she said she felt 99% sure she was cancer-free. Her last round of chemo ended on September 27, 2022. She said she couldn’t wait to move aboard and start a new adventure. On October 7, 15 days later, Snow Goose cast off her docklines and headed south.