Advertisement

Exhaust manifolds are important, and ignoring them can potentially lead to expensive problems, perhaps an engine rebuild.

Exhaust manifolds last forever, don't they? Even if they do fail, it isn't a major problem, right? These are common reactions when people are asked about their boat's manifold. There is an additional hassle-manifolds are normally damaged by corrosion, so they're not covered by your insurance policy.

All of this makes the outlook seem rather bleak. It's not as bad as it seems, though. All that's needed is a change in attitude. Rather than seeing it as a "sealed for life" component, view a manifold as a service item to be replaced at regular intervals. If you do this, major problems can be avoided.

Life Expectancy

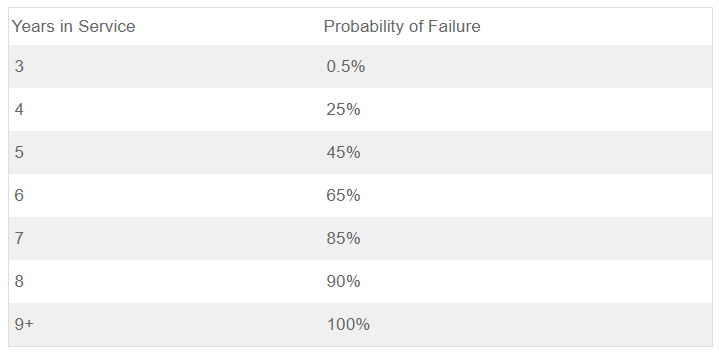

How long will a manifold last? Obviously the way you use your boat will be a factor, as will the type of water it's on. Saltwater boats are going to see a shorter manifold life when compared to their freshwater counterparts. Most experts suggest that a manifold will have a life expectancy of six to eight years. However, heavy use in saltwater can see this drop to as low as three years, while lightly used freshwater boats can get up to 20 years out of a manifold. (We are assuming that your manifold is raw water cooled. While it is the exception to the rule, some engines have a manifold cooled by the engine's fresh water/antifreeze coolant mixture. These obviously usually last much longer.) One thing is for certain, the older your manifold gets, the more likely it is to fail. This is clearly shown in the chart below which is for illustrative purposes.

Why So Fragile?

The manifold is a complex metal casting, actually a pipe within a pipe. It collects the extremely hot exhaust gasses directly from the engine into an inner "pipe" or long chamber which is usually cooled by raw water running through an outer casing. From here the hot exhaust gases and water are fed to the riser where the gases and water combine to continue their trip overboard. Without the cooling effect of the water, the hot gas would burn through a hose or thin wall pipe very quickly. Keeping the water and gases separate in the manifold is critical. If water finds its way into the gas-only section, it can enter the engine cylinders and wreak havoc with the internal engine parts.

Manifolds and risers live in an incredibly harsh environment. They endure very hot corrosive gases slamming into the manifold at high velocity. The water jacket portion of a manifold is intermittently exposed to hot saltwater and moist air, the perfect conditions for corrosion. All the time they're vibrating madly during running time and left idle for long periods, allowing rust to eat away at the metal. That they last as long as they do is impressive.

Symptoms

Before your manifold fails, you may get warning signals. Needless to say, you should take notice immediately. If your engine is difficult to start, produces white smoke, or runs roughly, water in the cylinders may be the culprit. If you ignore the situation, hydrolock may occur. This is when sufficient water has leaked into the cylinder that piston compression becomes impossible. Massive, and usually terminal, damage will result as you try to start the motor.

Inspection is always a good idea, and we recommend that you try to do so at least every two to four years. It may seem a little pointless since it's impossible to see into all the passages, but you will still get some clues about the extent of any corrosion. Your manifold may be blocked with the products of corrosion, for example, leading to "hot spots" in the cooling system and low-level overheating. These won't necessarily show up on your temperature gauge, but can result in a shortened engine life. Inspection is often a difficult job, requiring removal of plumbing components, removal of other components that may block removal of the manifold, removal of the heavy manifold and careful replacement of gaskets.

If your boat suffers more than average corrosion problems, then it may be more likely to suffer from premature manifold failure. Stray current corrosion is evidenced by rapid zinc wastage, corroding lower units and corrosion build-up on through-hull fittings. This is normally the result of poorly installed 12vDC wiring or faulty 12vDC equipment. Electrical problems should be corrected as soon as possible; the damage caused by leaky 12vDC wiring is potentially far worse than a broken manifold.

Manifold Replacement

Replacing a manifold is certainly a job that you can do yourself. It may take longer than you expect, though. Bolts may be rusted in place and other fittings may be in your way. It can turn out to be a day-long job. If this does not appeal to you, boatyards will tackle the job for you.

If you need to replace a manifold you can purchase one from the manufacturer of your engine but you can probably also get one from an after-life manufacturer for a lot less money. And it may be built to the same specs. Ask about this. You will need the make, model and serial number of the engine, the exhaust pipe diameter, and will need to order the necessary gasket kit, installation kit, and end plates if required.

A final word of warning: each year, owners (and mechanics) sink boats by leaving the exhaust ports unplugged after disconnecting the manifolds. Waves sloshing into the ports can sink a boat overnight. Hoses must be plugged and tied securely above the waterline to prevent water from flowing into the boat. With this in mind, consideration for your manifold will pay dividends in reliability and peace of mind, giving you seasons of trouble-free service.