Advertisement

The past decade has seen an amazing array of changes and improvements in outboard engines. If you haven't shopped for one lately, you're in for a nice surprise.

Hop in a time machine and go back to 2003 to buy an outboard. You'll find a vastly different marketplace, one dominated by carbureted two-stroke engines. They're gone now, relegated to the design dustbin by tightening emissions standards and changing consumer preferences. During the past decade, engine manufacturers have delivered an entirely new lineup of four-stroke power plants rated from 2 to 350 horsepower (plus one 557-hp monster), and added refinements to make them more suited to the demands of modern boats and boaters.

Evinrude's E-Tec line of direct-injected two strokes features a stratified-combustion mode that increases fuel economy while trolling or motoring at no-wake speeds.

But we're not entirely awash in a sea of four-strokes. Direct-injection (DI) two-strokes are alive and well — quite frisky, really — with offerings from Evinrude, Mercury, and Yamaha all competing for space on your transom. The good news for consumers is, no matter which brand or technology you choose, today's outboards will burn at least a third less fuel, run smoother and quieter than the ones we grew up with, and won't spew a cloud of blue smoke. That last bit is crucial, because the quest for a cleaner outboard drove most of the improvements made over that time, and some of the price increases as well.

Carburetor Becomes A Dirty Word

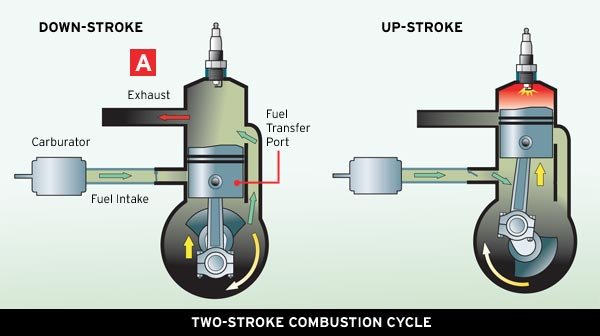

Before we delve much further into the differences between modern four-strokes, it's important to understand two things: why you can't buy a new carbureted two-stroke anymore, and why the original four-stroke engines generally weighed 20 percent more than a two-stroke of similar power. Traditional two-stroke engines have intake and exhaust ports on opposite sides of their cylinders; these are "opened" and "closed" by the edges of the piston (skirt) as it travels up and down. Really, they're blocked or unblocked, as the piston passes by the openings and, importantly, there are points in the process when both ports are open at the same time. That means that during the down stroke, when the fuel/air mixture is being drawn into the cylinder from one side, some of it passes unburned right over the top of the piston head, and out the exhaust port on the opposite side (illustration A below). These are, in emissions parlance, "unburned hydrocarbons," a fancy way of saying wasted gas and oil. With outboards being cooled by water drawn from the lake or ocean, and the exhaust gases mixing with that cooling water on its way out, this wasted gas and oil ends up in the water. The Environmental Protection Agency (EPA) put an end to this type of contamination with regulations that took effect in 2004, and became more stringent in 2007.

The spark plug fires on every upstroke in a two-stroke engine. you can see how the gas (green arrows) can pass right over the piston head from the right-hand side of the cylinder and out the exhaust on the left side during the down-stroke. (2013 Mirto Art Studio)

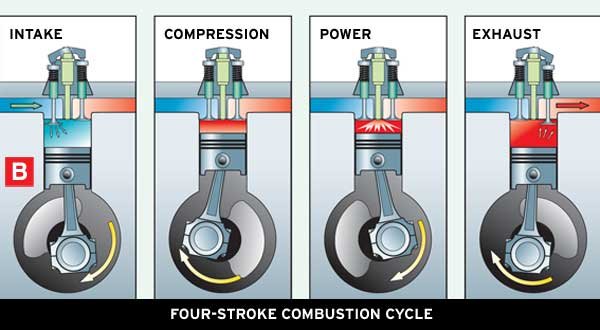

Four-strokes, on the other hand, use valves on the top of the cylinder — as many as four valves per cylinder, depending on the design, to introduce the air, and release the exhaust from the cylinder. Critically, the four up-and-down motions of the piston (or strokes) separate the intake and exhaust processes, so the fuel/air mix can't escape (see illustration B below). The result is far fewer unburned hydrocarbons. Engines that meet the 2013 standard produce on average 91 percent fewer emissions than old two-strokes. Making all those valves open and close at precisely the right time requires a whole complement of extra parts — camshafts, lifters, rockers arms, and so on. The result was also around 50 to 100 more pounds in parts in a midsize four-stroke compared with the simpler two-stroke.

Four steps are required for every power-stroke (firing of the spark plug). (©2013 Mirto Art Studio)

That's where things stood for a long time. Four-strokes were inherently cleaner and heavier, and two-strokes were lighter but dirtier. But Honda, Mercury, and Yamaha have all spent the past few years developing new four-strokes that perform and weigh comparably to two-strokes. And Evinrude, Mercury, and Yamaha have all developed two-strokes that are as clean running as a four-stroke. Each has pulled off a neat engineering trick.

Teaching An Old Camshaft New Tricks

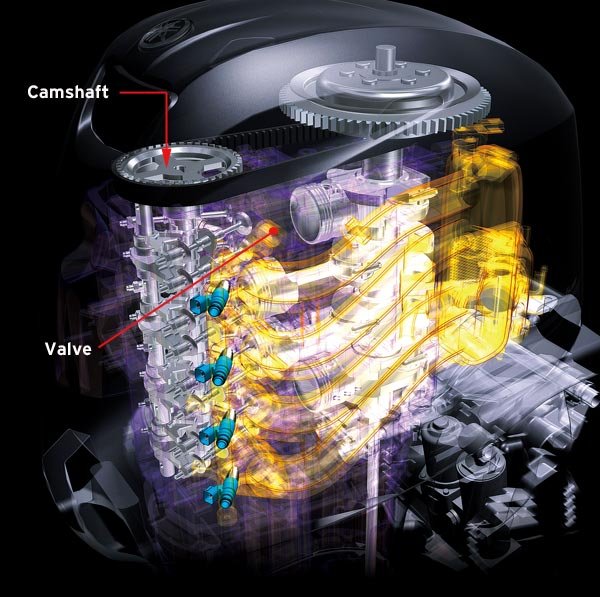

To understand how a camshaft dictates the power of an engine, it's important to know what it looks like. Picture a stack of nickels on your desk, maybe 18 inches high. Now carefully push just a finger's width of the middle of the stack off-center slightly and repeat up and down the stack. Now you have a stack of offset circles, which looks a lot like a camshaft, except that on a camshaft, they are oval in cross-section, not perfectly round. As the camshaft rotates, these ovals push on arms that pop the valves open and closed. The shape of the oval, or lobe, and its orientation on the shaft relative to the other lobes determine when the valve opens to allow air in (or exhaust out), how high it opens, and for how long. The camshaft's offsets dictate how the engine will perform, and the shape of the traditional camshaft can't be changed.

"In four-stroke engines, the amount of horsepower generated is driven by the camshaft," says Dennis Ashley, assistant national sales manager for Honda Marine. "A fixed-camshaft can be designed for low-end power or high-end power, but not both." Variable-valve timing is a way around that. In effect, it allows the camshaft to shift into a higher gear, which lets the engine work up to its full potential. Honda uses technology developed on the automotive side called VTEC, for variable valve timing and lift electronic control system. It's complicated, but the system effectively adjusts the shape of the camshaft, improving the power and performance of the outboard. It's like swapping out camshafts while the engine is running, allowing Honda's outboards to generate more power at high rpm, while still having low-end efficiency.

Honda developed the AMP+ system for the U.S. Coast Guard, which bumps the idle up 100 rpm when needed to provide more juice to the batteries.

Yamaha has taken a different tack, but still tweaks the camshaft to improve the performance of their four-stroke models, like the F200 that was unveiled at the end of 2012. They use variable-camshaft timing, where the camshaft is rotated to advance the lift of the intake valves. "It's like taking a big breath before trying to lift a heavy weight," says David Meeler, Yamaha's product marketing information manager. "It gives the engine a deep breath of fresh air, a great way to put mid-range punch and throttle response into an engine."

A computer rendering of the new Yamaha F70, showing the single-camshaft design, where the camshaft opens and closes both the intake and exhaust valves.

Mercury decided to try to get more horsepower out of less displacement, using a supercharger to force more air into their Verado outboard in 2004: "A four-stroke takes twice as long to perform the same engine operation as a two-stroke," says Steve Miller, senior category manager for Mercury Outboards. "With the technology at the time, we wanted the performance of a two-stroke with the four-stroke benefits. When we considered the supercharger versus a turbo as a means of boosting performance, we found the turbo needs exhaust to spin up, so it doesn't respond as quickly. The supercharger also poses no heat issues. So we designed the engine with oversize cranks and bearings to be supercharged."

The other side of the performance coin is weight. Due to their complexity, and the need for parts like an oil sump and pump, four-strokes must shed weight in other areas to have the same horsepower-to-weight ratio as a two-stroke. One strategy is to squeeze more power out of a smaller block, like Mercury's Verado. Another is to put an existing design on a diet, rigorously examining each part for excess weight. Yamaha has pursued a combination of these strategies recently, and the results are striking.

A few years ago, Yamaha's flagship 350-hp outboard and the 300-hp version of it were based on eight-cylinder blocks. But at the end of 2009, they introduced a 4.2-liter V6 outboard that put out 300 horsepower, and weighed around 250 pounds less than its V8 predecessor. Besides extracting nearly the same amount of power from fewer pistons, thanks in part to larger-bore, longer-stroke, and well-thought-out air-intake design, they also shed weight throughout the V6, from the cowling to the cylinder sleeves. They've even reduced the weight of the alternator by using smaller, more powerful, rare-earth magnets (more on this later). Their new four-cylinder F200, released last fall, continued the trend, shedding nearly 120 pounds compared with their earlier V6-powered 200-hp models. In fact it's just 14 pounds heavier than their 200-hp, DI two-stroke model.

Different Strokes For Different Folks

You'll notice all of these manufacturers are trying to design an outboard that "performs like a two-stroke," which is precisely the reason that two-strokes haven't gone away, just cleaned up their act. Direct injection (DI) is the innovation that allows a two-stroke to run cleanly and efficiently. By separating the fuel injection from the intake of air into the cylinder and, more importantly, waiting until the piston has risen far enough up the cylinder bore to block the exhaust port before injecting the gas, a DI two-stroke doesn't blow any unburned gas right through the cylinder and out the exhaust like its carbureted cousins. And because this process is electronically rather than mechanically timed, the engineers can tweak the performance with software rather than wrenches.

While Mercury offers Optimax DI two-strokes and Yamaha still has their "High Pressure Direct Injection" two-stroke engines in their lineups, Evinrude has chosen to offer only DI two-strokes, called E-TEC. Karl Sandstrom, product manager of Evinrude Outboards, says that using computers to control engine timing, and the smallest details of when and how combustion happens, allows them to adjust for maximum efficiency under different operating conditions. "Forty percent of an outboard's duty cycle is at or near idle speed, either trolling or motoring in no-wake zones," he says. "With the computer power we have, the engine can act like a very small outboard when all that power isn't needed, then switch to homogeneous mode when it is."

Mercury's Optimax engines are beloved by bass fishermen for their quick throttle response and fuel-thrifty ways.

At idle, he says, the computer can tell the engine to inject only a tiny amount of gas, far less than needed to create a combustion event that would fill all the space above the piston, which is typical. Instead of a big bang, you get a little pop, enough to keep the piston moving (stratified combustion). But hit the throttle and the engine switches to homogeneous (all the same) mode, and enough fuel flows to make the combustion event fill the entire space. This fuel-saving strategy has even made its way into newer-model cars.

Meeting The Demands Of Modern Boaters

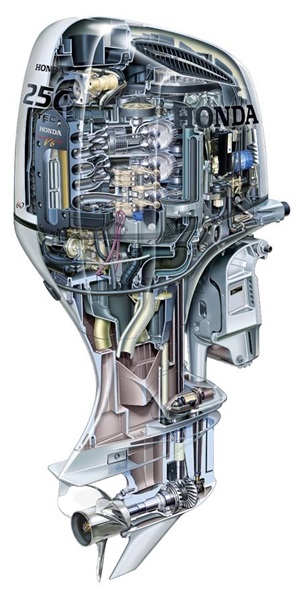

A cutaway of Honda's BF250 shows a special air-intake

design that allows a belt-driven fan at the front of the

engine to take cooler out-side air and funnel it to the

engine, generating more horsepower.

(©2013 Mirto Art Studio)

As the industry refines and improves outboard technology, they haven't ignored the changes in how boats are equipped and run. In particular, the demands put on a boat's electrical system have risen as more and more boaters equip their boats with large-screened multifunction displays and all the accompanying gizmos. Electronics manufacturers have built fancier and fancier equipment that sucks more and more juice to satisfy gadget-loving boaters, forcing outboard engine makers to find innovative ways to provide all that power.

First and foremost, outboards have become more energy efficient themselves. Using less electricity for internal operations means there's more left over to charge the battery and run your chartplotter, sounder, radar, stereo, iPod, VHF, AIS, night-vision camera, and so on. But even so, more powerful alternators are needed. Honda has created a system they call Amp+, which senses the electrical load on the battery and bumps up the idle speed of the engine if necessary. Yamaha started using those aforementioned rare-earth magnets that make 13-percent more power, but reduce the weight of the alternator by 10 percent. But perhaps the most far-reaching development, not directly related to the engine, is the rise of electronic engine controls, also called "fly-by-wire."

No More Cables

No matter what you call it, using electrons rather than a metal cable to change throttle positions, steer, and shift your outboard has numerous benefits. Chief among these is that it eliminates the burden of routing through the bowels of your boat one or more stiff, unforgiving mechanical controls that will eventually freeze up due to rust.

"You can tie 12 granny knots in a digital throttle and shift cable, and it will still work," says Mercury's Miller. But digital control means more than simpler rigging. All sorts of useful benefits, including automatic dual-engine synchronization, single-lever control options, steady-speed presets for towing skiers, and perhaps the most popular, joystick control, all derive from letting the computers talk to the outboards.

The digital link between throttle, shift, and steering controls spills over into the instruments and gauges as well. Gone is the need for four or more separate gauges on the dash to monitor critical outboard information. Single, wide-screen gauges with preset and programmable displays can show more and better information than an analog-gauge cluster. Today's display screens can also learn. "The Smartcraft gauge clusters don't just tell you how much fuel you're burning," says Miller. "It learns your boat. The gauge coaches you toward your fuel-efficiency sweet spots." It can even remember optimal trim settings.

The Coming Decade

As outboard manufacturers further refine their offerings, we'll continue to see improvements in performance, efficiency, and power output. Many in the industry expect the EPA to apply the same emissions standards to outboards in 2018 as they recently did to inboard engines, which would make a catalytic converter necessary. To accomplish this, manufacturers would have to switch to closed-loop cooling, like on an inboard engine. An engineering challenge to be sure, but Seven Marine, a newcomer to the outboard market which marinized a GM 8-cylinder engine, already offers closed-loop cooling on their 557-hp outboard and a horizontal engine orientation, both of which are unique in today's market. Given the remarkable changes in the past 10 years, those may not be unique attributes for long.

The Repower Predicament

So which outboard is right for you?

Repowering right means sorting through the many options now available to find the one that best matches your boat, the way you use it, and your brand preferences. You'll want to consider the following:

Boat design. Your engine choices will be limited by the weight your boat can carry, the horsepower it can handle, the space you have on the transom, the fiberglass work necessary to mount the new engines, and the structure at the stern.

Duty cycle. Stratified combustion will save fuel if you spend most of your time trolling; mid-range punch will be better to get you through a choppy inlet or out to your offshore fishing grounds.

Maintenance schedules. In general, DI two-strokes will have longer intervals between scheduled services because they lack mechanically controlled drive trains that need adjustment every 500 to 1,000 hours.

Electrical demand. If you want to keep those fancy electronics running all the time, make sure to check not only the rated amperage output, but also output at lower rpm, where it could be half of what it is at cruising speeds.